A Sudbury mine-tech company is developing a new system to inventory and sanitize personal protective equipment (PPE) in response to the COVID-19 pandemic.

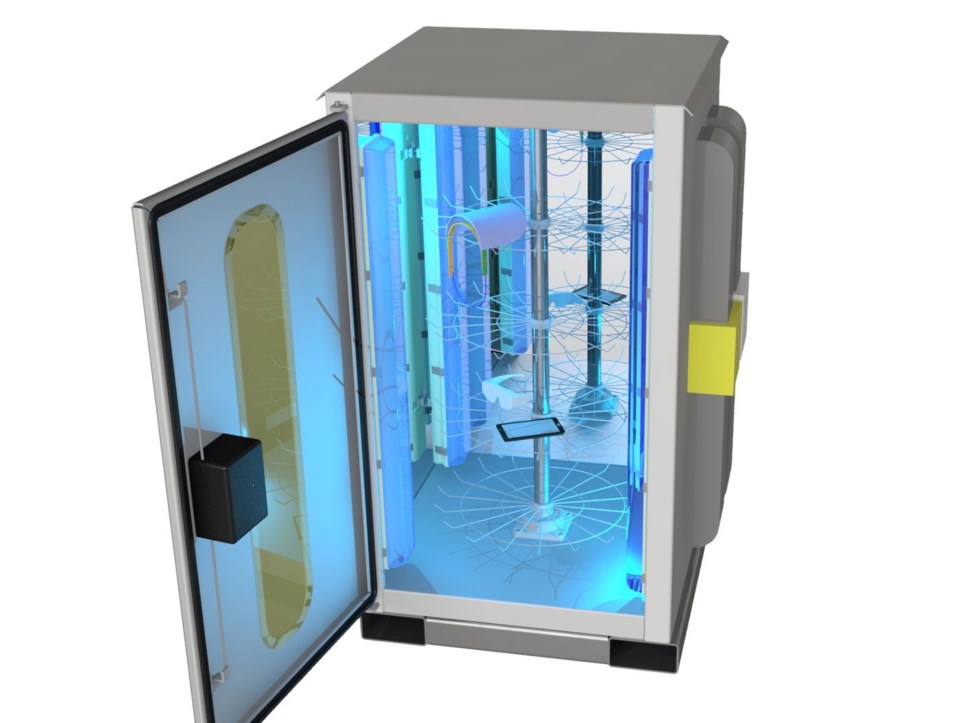

FORTAI’s Sanitation SmartCube will be able to sanitize PPE, while also keeping an inventory of what PPE is being used.

The SmartCube has been in development for the last two years, but company president Trang Tran-Valade said that, given the ongoing pandemic, the company wanted to contribute tech that would help contain its spread.

“With the current situation and with the call for innovators to come together and collaborate and really put forth solutions that can help, we felt compelled to evolve our product towards this current application,” Tran-Valade said.

The SmartCube is a box that uses artificial intelligence to track data about what is added to, or removed from it – in real time.

But now, instead of monitoring mining inventory, FORTAI will enable the SmartCube to sanitize PPE, clothing, or tools, while keeping track of what is being sanitized and how often, Tran-Valade noted.

The product will be portable and can be made according to each client’s needs.

That means where one client might want a tabletop version the size of a microwave, another could have a stand-alone unit as big as a refrigerator.

It all depends on where it will be situated and how it will be used, Tran-Valade said.

Once a client has placed an order, she estimates the product would be able to go into production within 30 days.

FORTAI’s area of expertise lies in serving the mining industry, but the Sanitization SmartCube is being designed with versatility in mind.

“You can imagine all the different places that you might want to have a unit like this; it doesn’t have to be only in one central place,” said Lynn Bulloch, the company’s communications manager.

“It could be at a remote site; it could be at a clinic somewhere; it could be in a First Nation – it could be anywhere.”

The Sanitation SmartCube is still somewhat early in the development process, and FORTAI is seeking partners that can lend their expertise to the project.

For example, the company is still researching the best method to use for the decontamination process.

Tran-Valade said the choices have been narrowed to a few that have been proven effective at fighting past viruses.

“That said, there’s nothing that’s been proven to fight specifically COVID,” she emphasized, “and that’s why we’re working with partners and scientists to be able to choose the best method or a combination of methods.”

Already on board are Laurentian University and the Perdue Central Analytical Facility, whose researchers are contributing their expertise in UVC (ultraviolet C) and heat ozone applications, Tran-Valade said.

But FORTAI would welcome collaboration with researchers who have connections to testing facilities so the company can validate the technology and ensure the proper certifications are in place.

The company’s primary focus markets are the mining industry and local health-care facilities, she noted.

In the week since FORTAI went public with its plans, interest is already growing, and the feedback has been positive.

“We are overwhelmed and very happy with the support we are receiving, and we hope to be able to truly make a difference and save some lives in the near future,” Tran-Valade said.